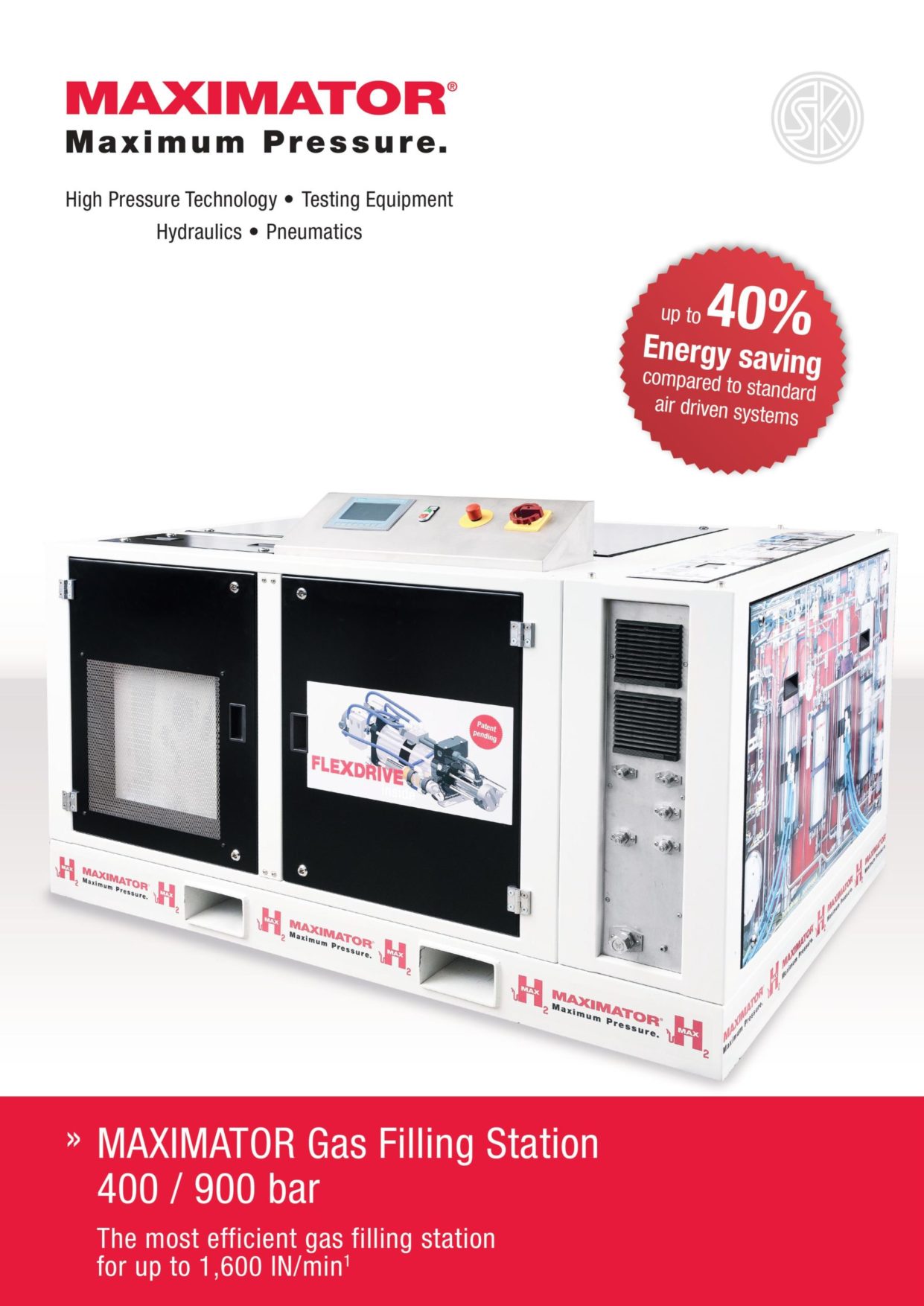

GFS – Gas filling station

Our Smart Gas Filling Station is driven by Maximator Efficency Drive Technology (EDT) which enables an unmatched cost and energy efficient for small scale or fleet applications up to 900 bar. Besides EDT as a drivetrain another unique and patented feature is

included which is called Flexdrive. This additional feature on the one hand increases energy and cost effiency and on the other hand optimizes the overall availability of the Gas Filling Systems.

We designed this gas filling station especially for small scale filling processes for e.g. Hydrogen refuelling in labaratory applications, drones, small fleet FCEV´s and home energy storage solutions and many more.

Efficiency Drive Technology

The Efficiency Drive Technology (EDT) is based on a closed loop drive system which increases the efficiency of the nitrogen or electro hydraulic operated gas boosters significantly and reduces the energy required for the drive. Nitrogen, required for purging and drive is already on board. The integrated frequency converter ensures maximum efficiency along the complete working range of this systems.

Safety

Within the Gas filling Sytems there is a strict separation between ATEX and NON-ATEX areas. All necessary sensors and an intelligent purging ensures a high level of satefy. Moreover the entire MAX Smart Refuel system is controlled by a safety PLC.

Water cooling

Thanks to intelligent water cooling, the temperature increase during gas compression is very low, which protects components, seals and increases the service life of the gas boosters.

Flex drive

This patent protected drive modification for efficient filling processes is specially developed for Maximator gas boosters with two air drive sections. Depending on the current conditions, only the required numbers of air sections will be activated by the PLC.

| GFS 56 | GFS 400 | GFS 2500 | GFS 5000 | GFS 900 | GFS 9000 | |

|---|---|---|---|---|---|---|

| Pressure class | 400 bar | 400 bar | 500 bar | 500 bar | 900 bar | 900 bar |

| Tº difference | 5ºC | 5ºC | 5ºC | 5ºC | 10ºC | 10ºC |

| Volume flow (N₂) @ 40 bar supply | 25 L/min | 200 L/min | 800 L/min | 1.600 L/min | 200 L/min | 1.600 L/min |

| Mass flow (H₂) @ 40 bar supply | 0,14 kg/h | 1,0 kg/h | 5,0 kg/h | 10,0 kg/h | 1,0 kg/h | 10,0 kg/h |

| Power consumption | 4 kW | 8 kW | 22 kW | 30 kW | 11 kW | 30 kW |

| Dimensions /mm | 1.500 x 1.500 x 2.000 | 2.000 x 3.000 x 2.000 | 2.000 x 3.000 x 2.000 | 2.000 x 3.000 x 2.000 | 2.000 x 3.000 x 2.000 | 2.000 x 3.000 x 2.000 |

| Weight | 1.800 kg | 2.800 kg | 3.600 kg | 4.100 kg | 3.100 kg | 4.100 kg |

| Control system | Safety PLC + Web application | Safety PLC + Web application | Safety PLC + Web application | Safety PLC + Web application | Safety PLC + Web application | Safety PLC + Web application |